How we work with transparency and trust

For us in Skretting, it's essential to increase the transparency and traceability of food production along the supply chain. Combining the latest technology and science with the dedication of our staff to produce the highest quality feed, we do our utmost to ensure that our business operations adhere to our own strict environmental guidelines. Nutrace® is Skretting’s unique, global feed-to-food quality and safety system. It ensures consistency throughout the production process, from raw materials to final feed solutions. Built on five strong pillars, Nutrace ensures that our customers and end consumers can have full confidence with regard to feeds in the farmed fish and shrimp value chain.

Ensuring food quality and safety - Nutrace

Nutrace® is Skretting’s unique company-wide management program that ensures feed-to-food quality and safety. Nutrace is continuously evolving to ensure that all potential risks associated with Skretting’s fish and shrimp feed production are minimised, and that any irregularities are found quickly and acted on. This unique concept allows our customers and end-consumers to have full confidence in Skretting as a transparent and trustworthy partner.

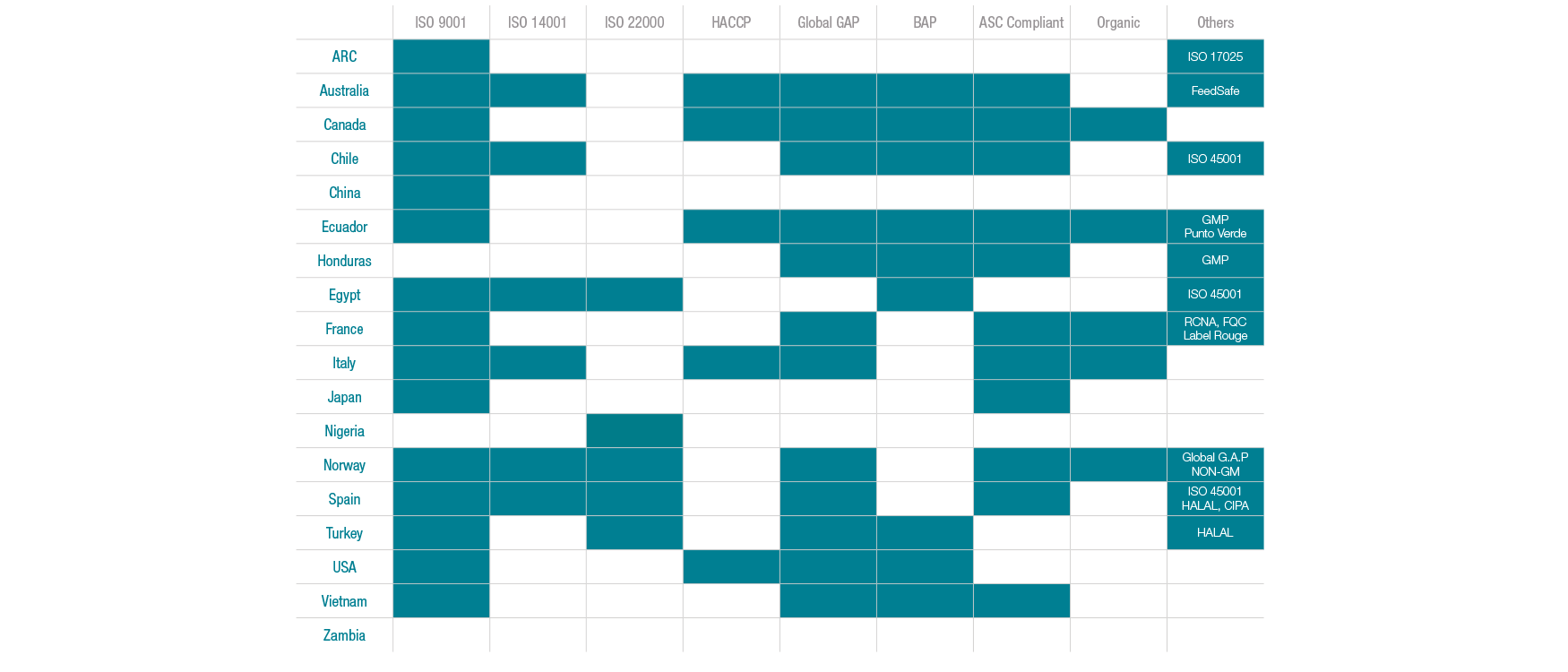

All internal operations are audited and all suppliers undergo a comprehensive evaluation and approval process to ensure premium-quality, renewable and responsibly managed resources. We conduct robust analyses and have full traceability of all approved raw materials - at delivery, throughout the formulation process, and up to the point of feed delivery.

Certifications and standards