A core objective in global operations is to support local operations as they build high levels of competence among the people operating our plants. Through this competence, and with high levels of participation in global projects, we fully expect to achieve our operational targets and be world leaders in fish and shrimp feed production. Skretting has always maintained strong collaborative global networks, working across many different disciplines. Local teams have faced many common challenges, and this has promoted a high level of sharing and listening at all levels.

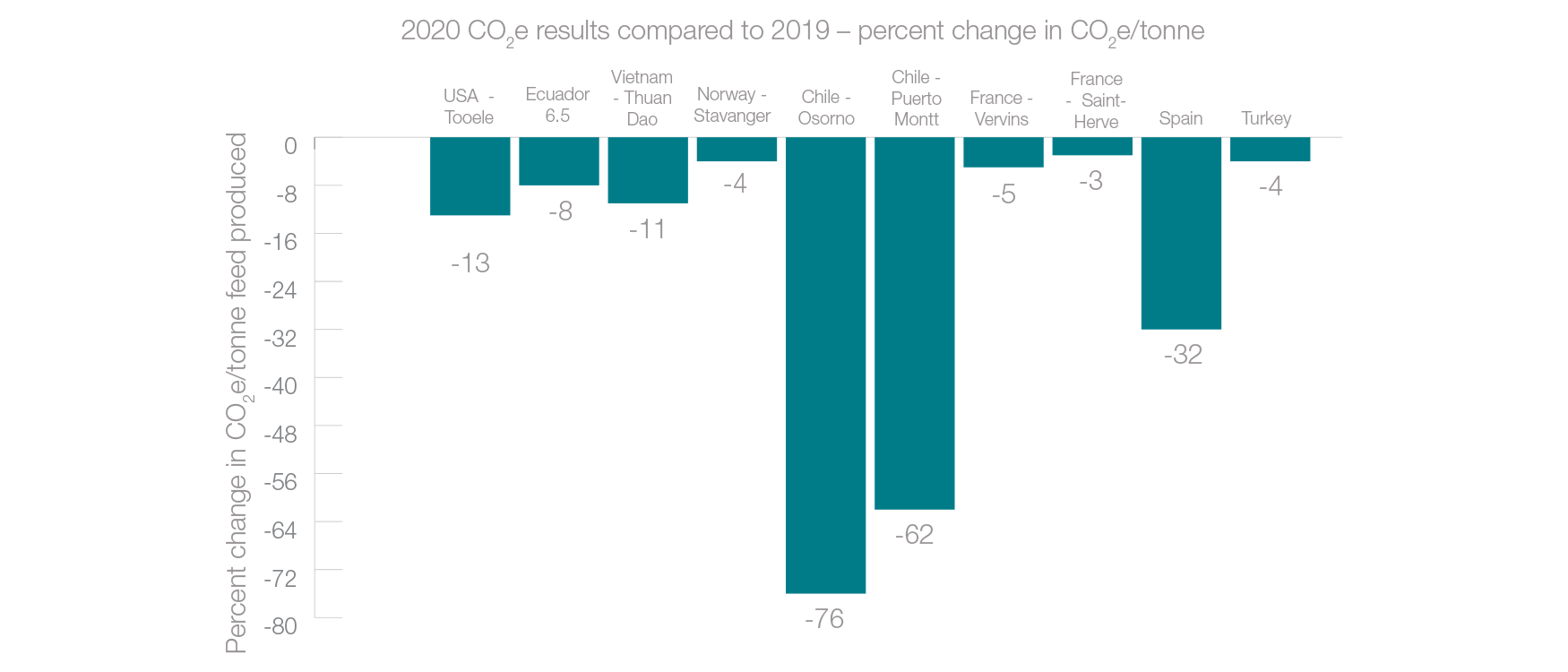

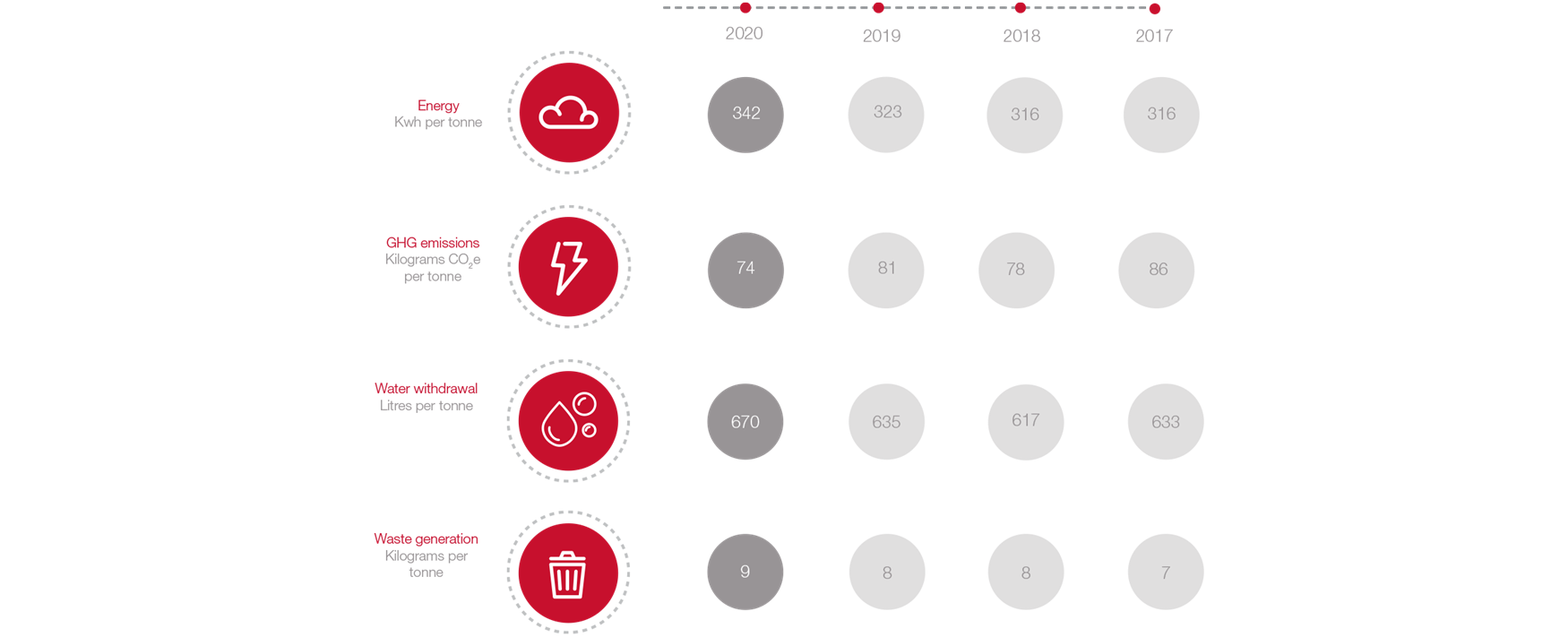

Our footprint is always evolving, with new production facilities under construction, closures or plant extensions underway in most regions. We continually monitor and report four key environmental KPIs, the data quality of which is continuously improved by having a third party taking a critical look at our reporting process. Two of the largest global projects in 2020 were energy reduction and KPI measurement.

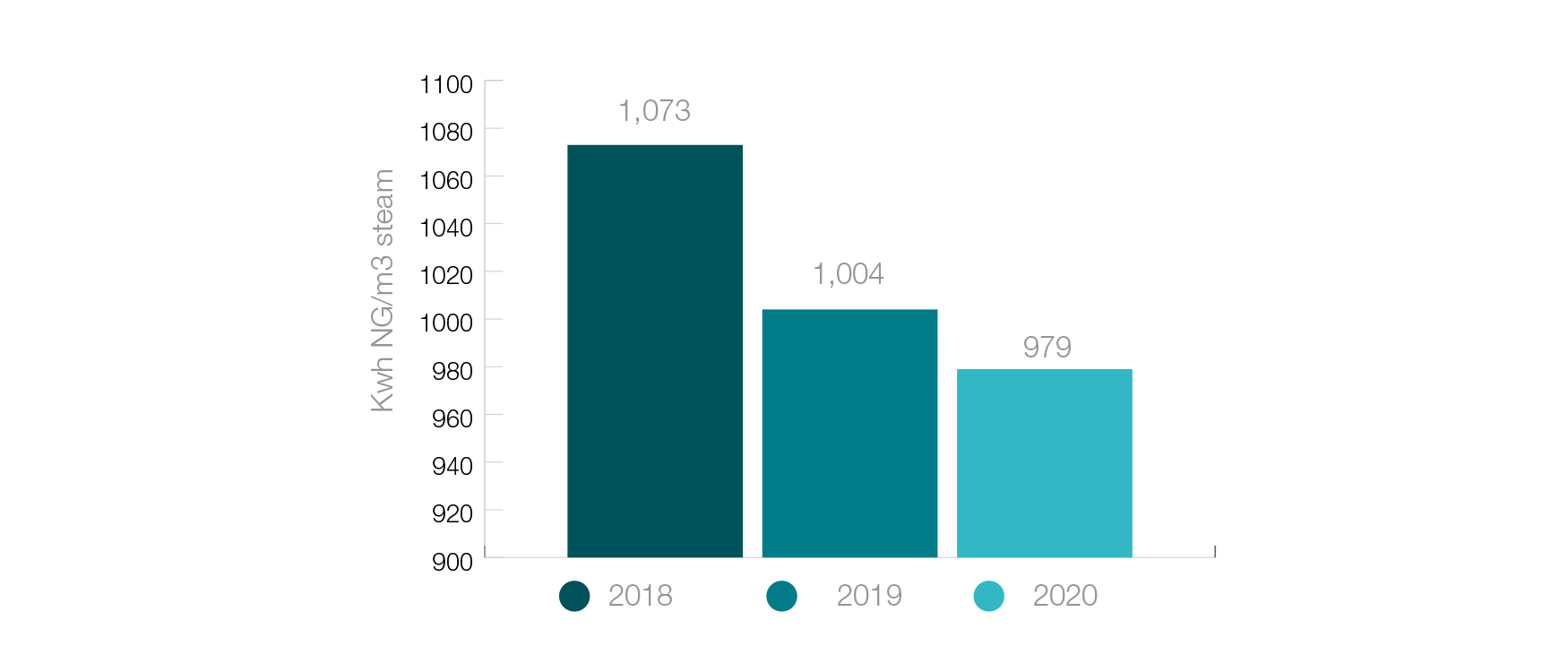

Our local teams have many projects focused on energy reduction. Successful projects are presented globally and, where appropriate, taken up by other plants so that they too can benefit from them. To-date, the largest energy saving gains have been made in the areas of steam boiler efficiency, dryer operation, and heat recovery solutions. Projects in these areas are having the largest impact on production kWh per tonne. Below is an example showing gas reduction in Skretting Spain over the last three years.