Let's get cooking! (and mixing, drying, grinding... you get the idea)

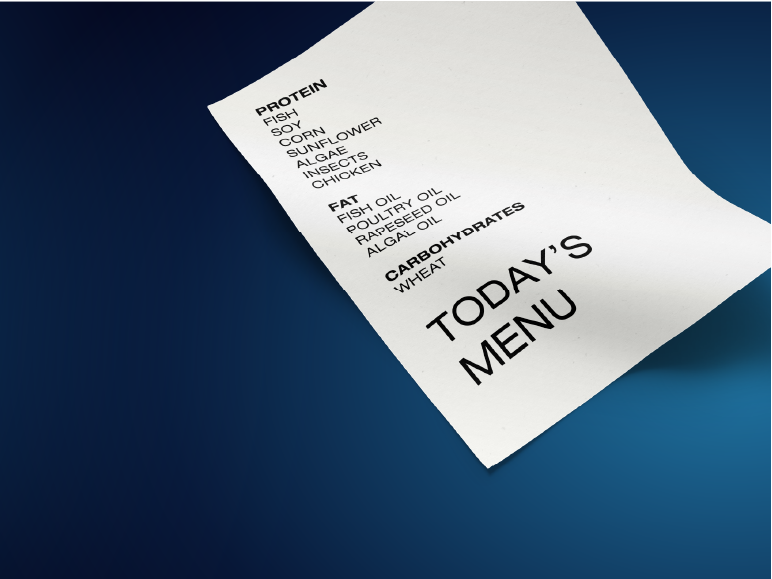

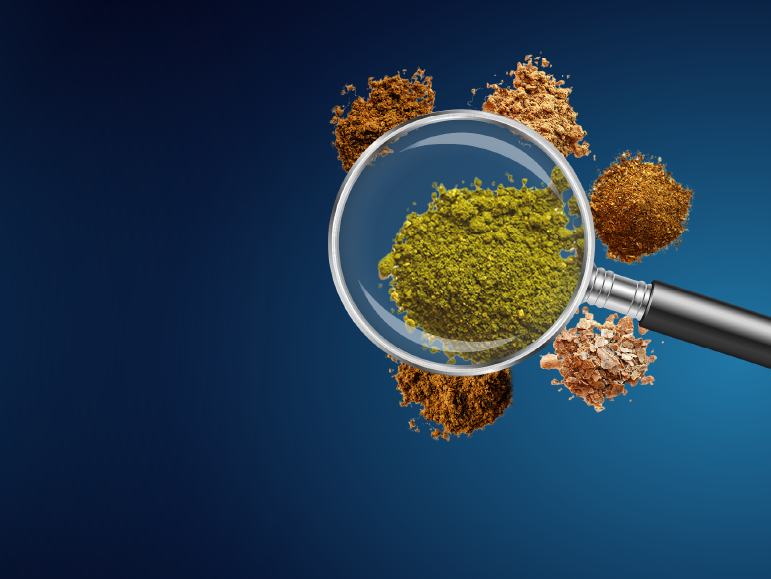

Our aquaculture feeds are formulated with recipes that include many different raw materials based on recommendations from expert nutritionists. However, in addition to the specific nutritional characteristics, we also have to consider the physical. An ingredient can have the best nutritional profile in the world, but if we can’t move it through our factory, things get tricky.

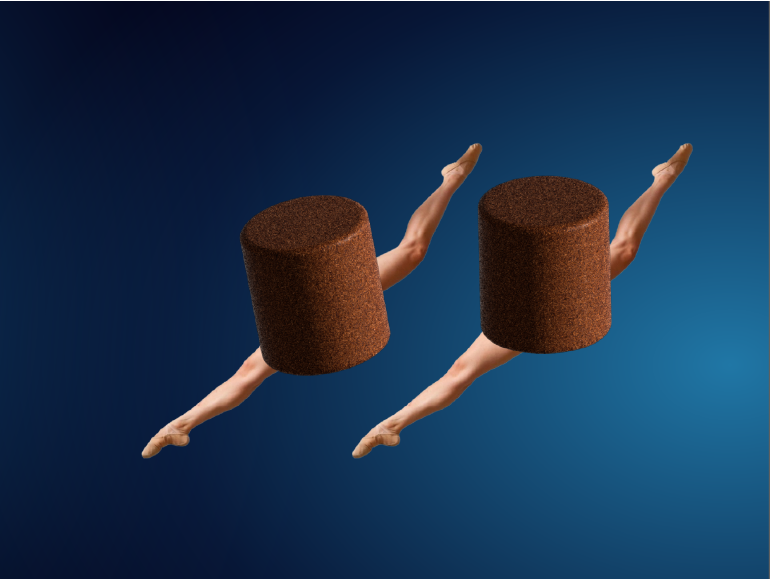

Developing knowledge on production processes and technologies is important to create new feed concepts, and increase the flexibility and functionality of our diets, without compromising physical quality for all the different farming systems. Feed production is quite a process, and it all starts with a recipe…

Next: In the water

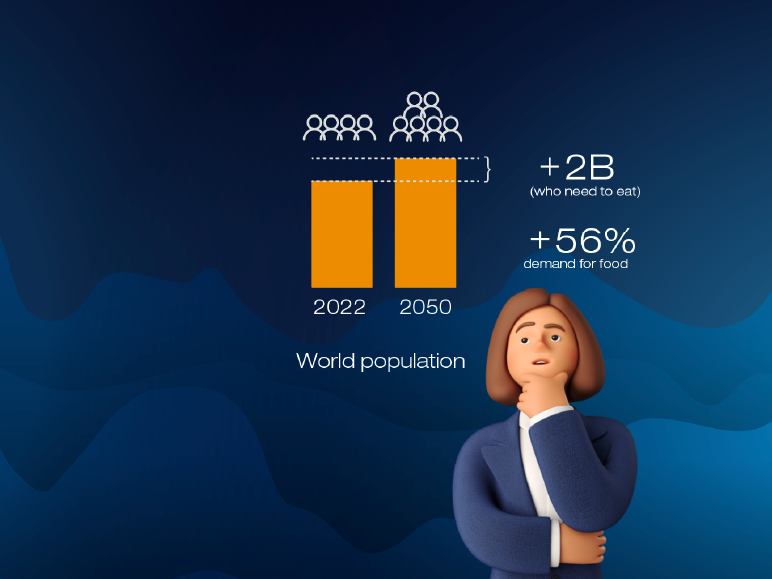

Well balanced, nutritious, healthy: the food requirements of fish and shrimp are the same as they are for people. In fact, we use a lot of the same equipment to make our aquaculture feeds as are used to make human feed food. The biggest difference? Our feed has the added complexity of being submerged in water, meaning it must be robust enough to handle feeding systems, while remaining palatable so the fish and shrimp want to eat it! A difficult balance, but one we have mastered.