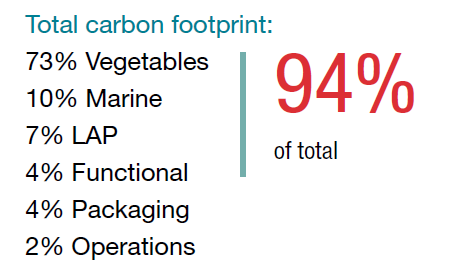

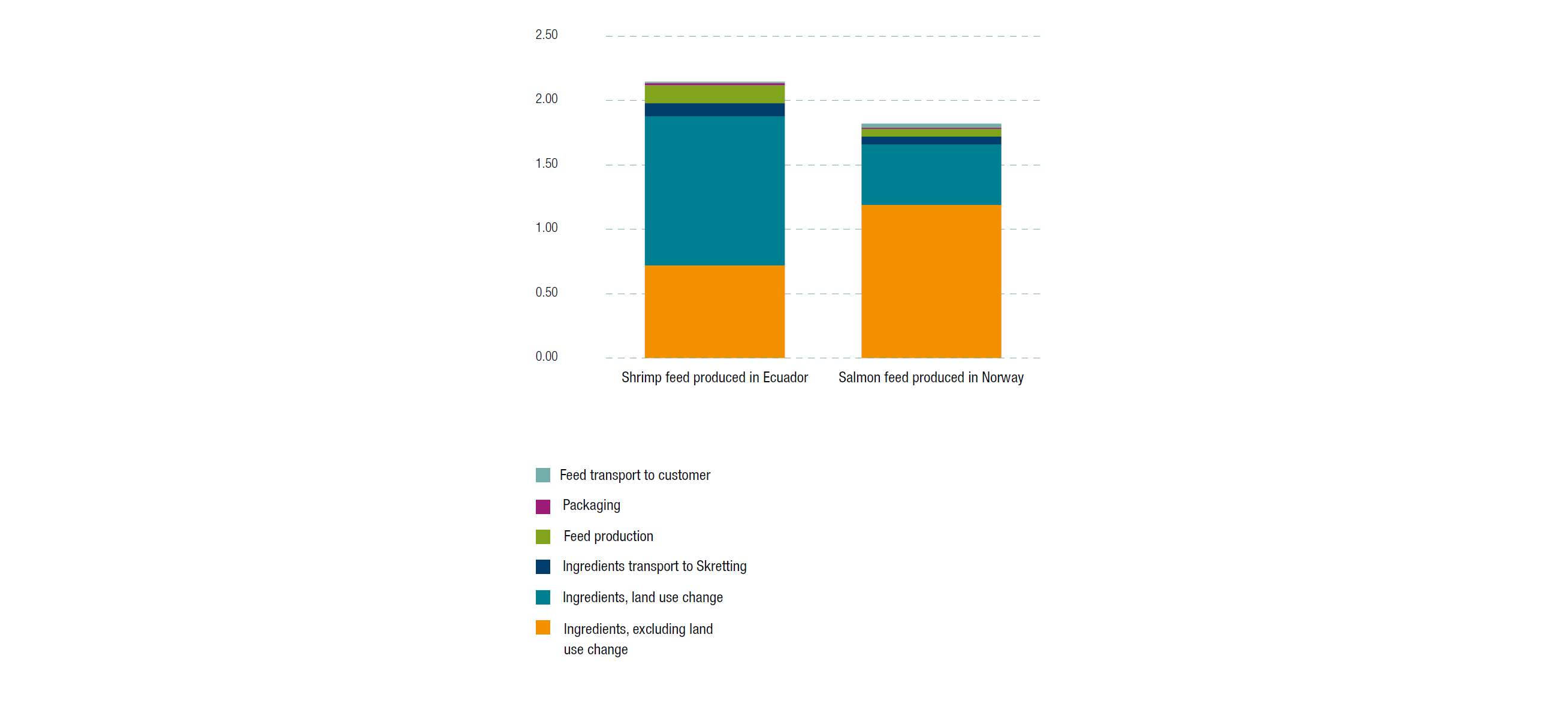

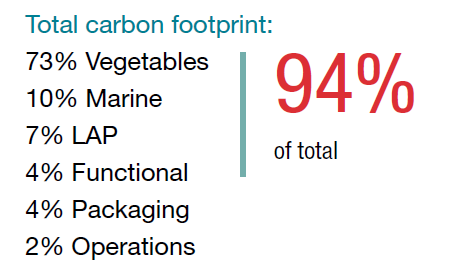

The largest share of the feed footprint is linked to the feed ingredients. For Skretting in total but also for most of our products, more than 90% of the footprint is caused upstream of our gates. This is a challenge because we only have indirect influence on this part. For example, we cannot directly determine which energy source our suppliers shall use or how farmers even further up the value chain cultivate their fields.

The largest share of the feed footprint is linked to the feed ingredients. For Skretting in total but also for most of our products, more than 90% of the footprint is caused upstream of our gates. This is a challenge because we only have indirect influence on this part. For example, we cannot directly determine which energy source our suppliers shall use or how farmers even further up the value chain cultivate their fields.

However, at the same time, we see this as an opportunity. Knowing about this hotspot allows us to focus more energy on our procurement, integrating environmental metrics in procurement systems and, based on this, define clear sustainability targets for our purchasing teams. With this, we have a great chance to significantly drive the reduction of the footprint of the whole feed and fish/shrimp value chain.

Quantifying and understanding the ingredient’s footprint is not easy though, as there is a high diversity of feed ingredients, an even higher range of production processes and thus, potential environmental impacts linked to them. Next to this, as we do not have direct influence over these processes and access to primary data is currently limited, we need to rely mainly on average secondary data. This comes with uncertainties that need to be known and understood to improve data quality but also to not draw wrong (and probably expensive) conclusions based on weak data.

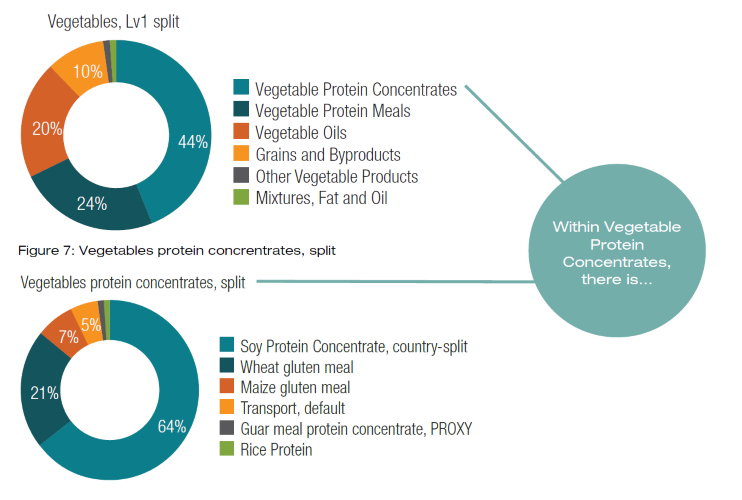

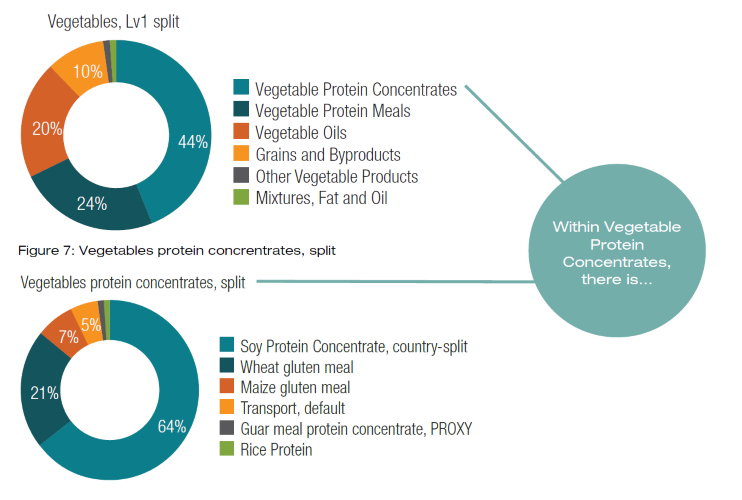

Based on carbon footprint analyses we did on the organisational level and for different feeds over the past year, we learned that the ingredient’s footprint is mainly driven by vegetable ingredients. This is mainly, but not only, due to land use change effects.

According to current LCA standards, greenhouse gas emissions linked to direct land use change (dLUC), which means the transformation of for example forest or grassland to cropland, has to be considered when it happened within the last 20 years. Land transformation can lead to significant environmental impacts, for example due to the cutting (and thus the loss) of biomass (above-ground but also below-ground like roots) and especially also due to the following change of soil carbon pools while adapting to the new situation.

These emissions can last for many years after the land has been actually transformed.

Deforestation is a global problem that also drives the carbon footprint of some important feed ingredients, like soy. Soy per se is an efficient crop that can have a smaller footprint (without land use change) than many other crops because of its ability to fix nitrogen from the air, which reduces the need for fertiliser. It can also be grown on land that is not suitable for many other crops. However, the demand of soy increased significantly in the past which also evidently caused deforestation, for example in the Amazon. As stated in our Soy & Oil Palm Ingredients Sourcing Policy, Nutreco is committed to facilitate the complete removal of any deforestation risk in our supply chains by 2025.

Despite reducing the land use change part, we are also exploring lower footprint ingredients across all categories. Even without land use change, vegetable ingredients, same as others, come with a footprint attached to them. Based on our database we are already identifying lower carbon ingredients per and across categories.

We will focus more on by-product ingredients, for example in the land-animal or marine ingredient categories. We also validate different novel ingredients regarding their footprints, availabilities and which conventional ingredients they might be able to replace within the different ingredient categories. Based on this information we will calculate realistic footprint reduction scenarios. It is not to forget that also novel ingredients have a footprint attached to them and that they have to be carefully validated to not move into a wrong direction.

The largest share of the feed footprint is linked to the feed ingredients. For Skretting in total but also for most of our products, more than 90% of the footprint is caused upstream of our gates. This is a challenge because we only have indirect influence on this part. For example, we cannot directly determine which energy source our suppliers shall use or how farmers even further up the value chain cultivate their fields.

The largest share of the feed footprint is linked to the feed ingredients. For Skretting in total but also for most of our products, more than 90% of the footprint is caused upstream of our gates. This is a challenge because we only have indirect influence on this part. For example, we cannot directly determine which energy source our suppliers shall use or how farmers even further up the value chain cultivate their fields.